The principle of quality tracking:

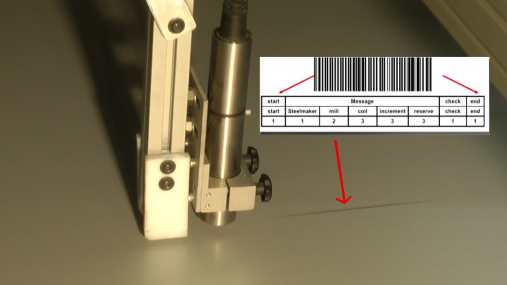

The Quality Tracking System uses unique 1D barcodes printed automatically along the coil at regular intervals – typically every meter. Quality information is then synchronized with the bar code to provide the position of a flaw. You may find more details in the e-brochure and the video.

European standard on quality tracking:

The European standard on quality tracking prEN10372 is going through the process of CE and its publication was expected in 2019. This standard ensures a common technical language between steel suppliers and steel users.

EDI for quality tracking:

One way of sending quality tracking information from steel suppliers to steel users is using EDI. The EDI structure for quality tracking is harmonized between 5 steel suppliers.

![]()

Upon request, these five steel companies can provide you quality tracking of steel coils to help you to optimize your overall steel efficiency and to improve your digitization process.

For further questions, please contact Danny Croon. Email: d.croon@eurofer.be